Simple, safe automation for packing, lifting and repetitive tasks in northern Ireland and Ireland

GMK Maintenance Services supplies, installs and supports Universal Robots collaborative robots (cobots) for real production environments. Cobots are ideal for automating repetitive, manual or hard-to-staff jobs such as packing, loading, lifting and machine tending — without the cost, space or disruption of traditional robot cells.

We focus on practical automation: systems that are easy to use, easy to maintain, and built to fit into existing production lines with minimal downtime. From first idea to installation, training and long-term support, GMK delivers automation that performs reliably in almost every production environment.

Our Services

Collaborative Robots

Universal Robots Range

Choose the right cobot for your application.

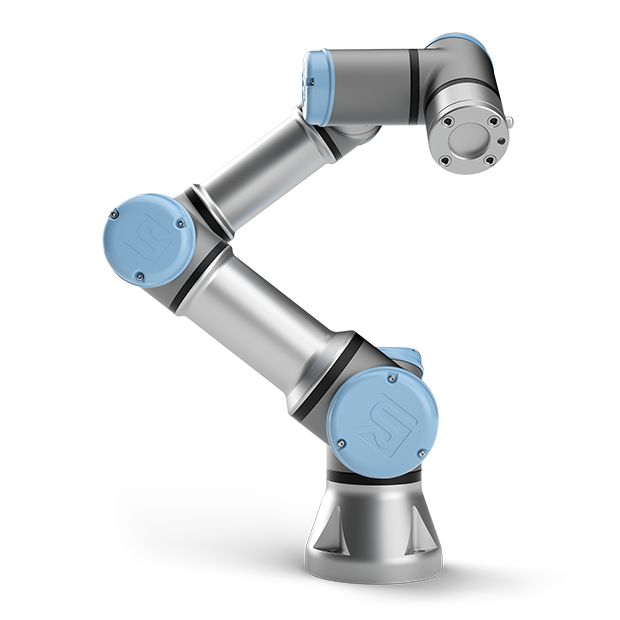

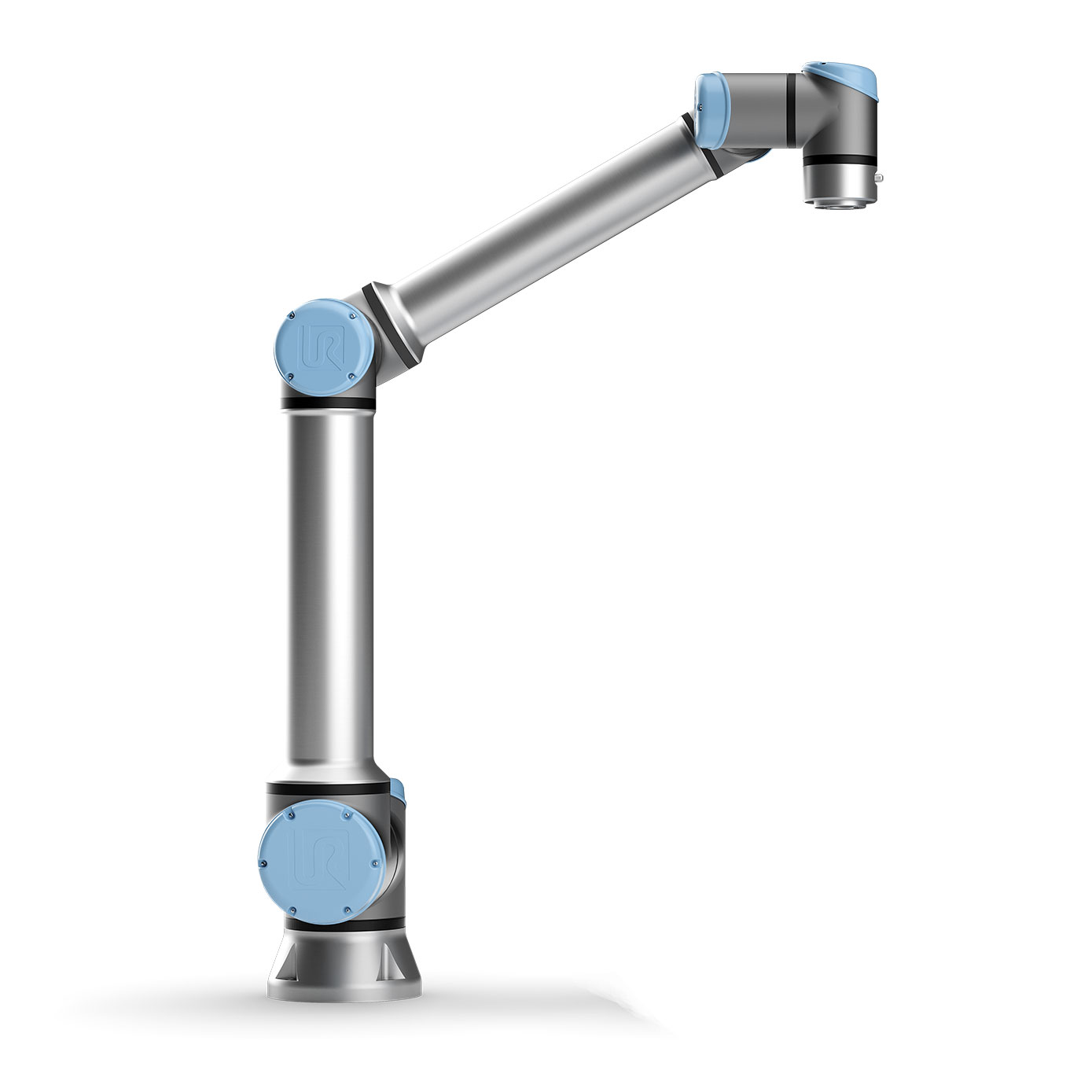

UR3e

Payload: 3 kg (6.6 lbs)

Reach: 500 mm (19.7 in)

Power: 300 W

IP rating: IP54

Safety: 17 configurable safety functions

Repeatability: ± 0.03 mm

Footprint: Ø128 mm

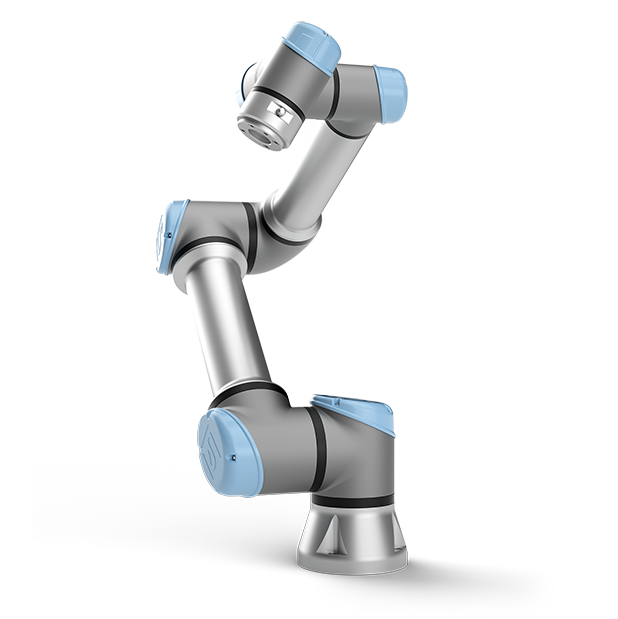

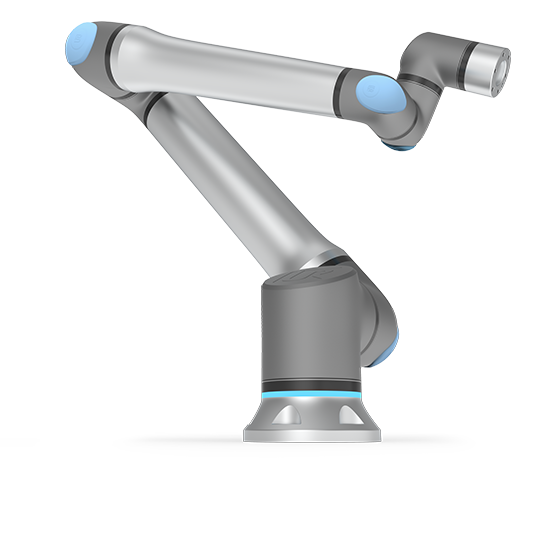

UR7e

Payload: 7.5 kg (16 lbs)

Reach: 850 mm (33.5 in)

Power: 570 W

IP Rating: IP54

Safety: 17 configurable safety functions

Repeatability: ± 0.03 mm

Footprint: Ø151 mm

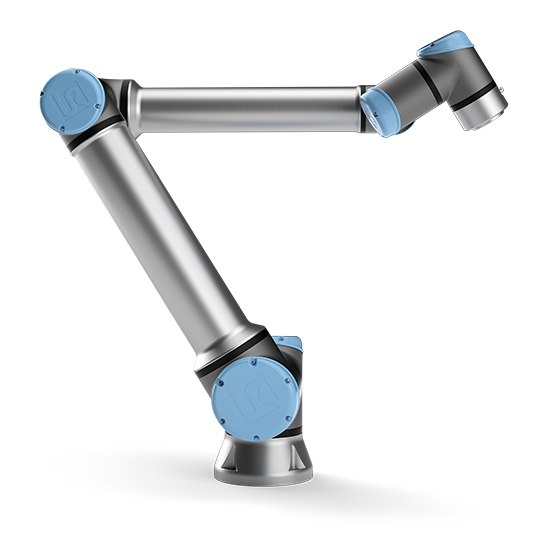

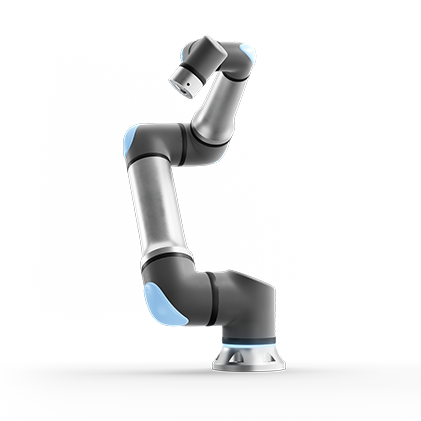

UR12e

Payload: 12.5 kg (27.5 lbs)

Reach: 1300 mm (51.2 in)

Power: 615 W

IP Rating: IP54

Safety: 17 configurable safety functions

Repeatability: ± 0.05 mm

Footprint: Ø190 mm

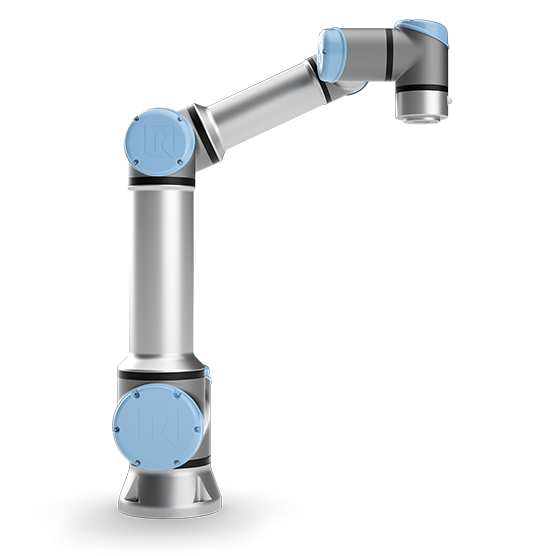

UR16e

Payload: 16 kg (35.3 lbs)

Reach: 900 mm (35.4 in)

Power: 585 W

IP Rating: IP54

Safety: 17 configurable safety functions

Repeatability: ± 0.05 mm

Footprint: Ø190 mm

UR15

Payload:15 kg (33.1 lbs)

Reach: 1300 mm (51.18 in)

Power: 550 W

IP Rating: IP54

Safety: 17 configurable safety functions

Repeatability: ± 0.05 mm

Footprint: Ø204 mm

UR20

Payload: 20 kg (44.1 lbs)

Reach: 1750 mm (68.9 in)

Repeatability: ± 0.1 mm

Power: 750 W

IP rating: IP54

Safety: 17 configurable safety functions

Footprint: Ø245 mm

UR30

Payload: 30 kg (66.1 lbs)

Reach: 1300 mm (51.18 in)

Repeatability: ± 0.1 mm

Power: 750 W

IP rating: IP54

Safety: 17 configurable safety functions

Footprint: Ø245 mm

Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ● Practical Automation For Production Lines ● Electrical & Controls Expertise ● Low-disruption Installs ● Local Support & Service Contracts ●

How It Works

Quick call – Understand your task, output and constraints.

Site visit – Measure space, safety and integration points.

Proposal – Clear scope, price and timeline.

Install – Low-disruption install and commissioning.

Support – Training, fault response and optional service & maintenance plans.