Industrial maintenance services in Moy

About B&C Services

Since 1975, B&C has specialized in the design and manufacturing of automated form-fill-seal machines for a wide range of granular and powdered products. With clients across food, chemical, agriculture, and construction sectors, we deliver reliable solutions trusted worldwide — from northern climates to desert environments.

B&C combine Italian engineering, deep industry expertise, and custom-built systems to meet even the most demanding production requirements.

Discover B&C’s High-Performance Packaging Machinery

Now Available Through GMK Maintenance Services! Looking for reliable, high-output form/fill/seal systems that can handle everything from bulky to granular to dusty products.

With Italian-engineered technology from B&C and local expertise from GMK, Irish businesses now have access to reliable, high-performance packaging and mixing system. Want to learn more about pricing? Contact GMK Maintenance Service for a free quote.

CV5010 Series

Compact and efficient, the CV5010 is ideal for small to medium-sized bags up to 3kg. This model offers flexible dosing options including cup dosing, screw-fed, or multi-scale weighing. With speeds of up to 60 bags per minute and a maximum bag size of 250 x 390 mm, it’s a smart choice for fast, accurate packaging of fine or granular products.

CV5025 Series

Designed for larger volumes and heavy-duty use, the CV5025 handles bags up to 25kg with ease. It supports belt, screw, and cup dosing systems, offering up to 35 bags per minute for 5kg and 25 per minute for 25kg. With a max bag size of 460 x 670 mm and optional airtight and watertight sealing, it's built for versatility across demanding production lines.

CV5080 Series

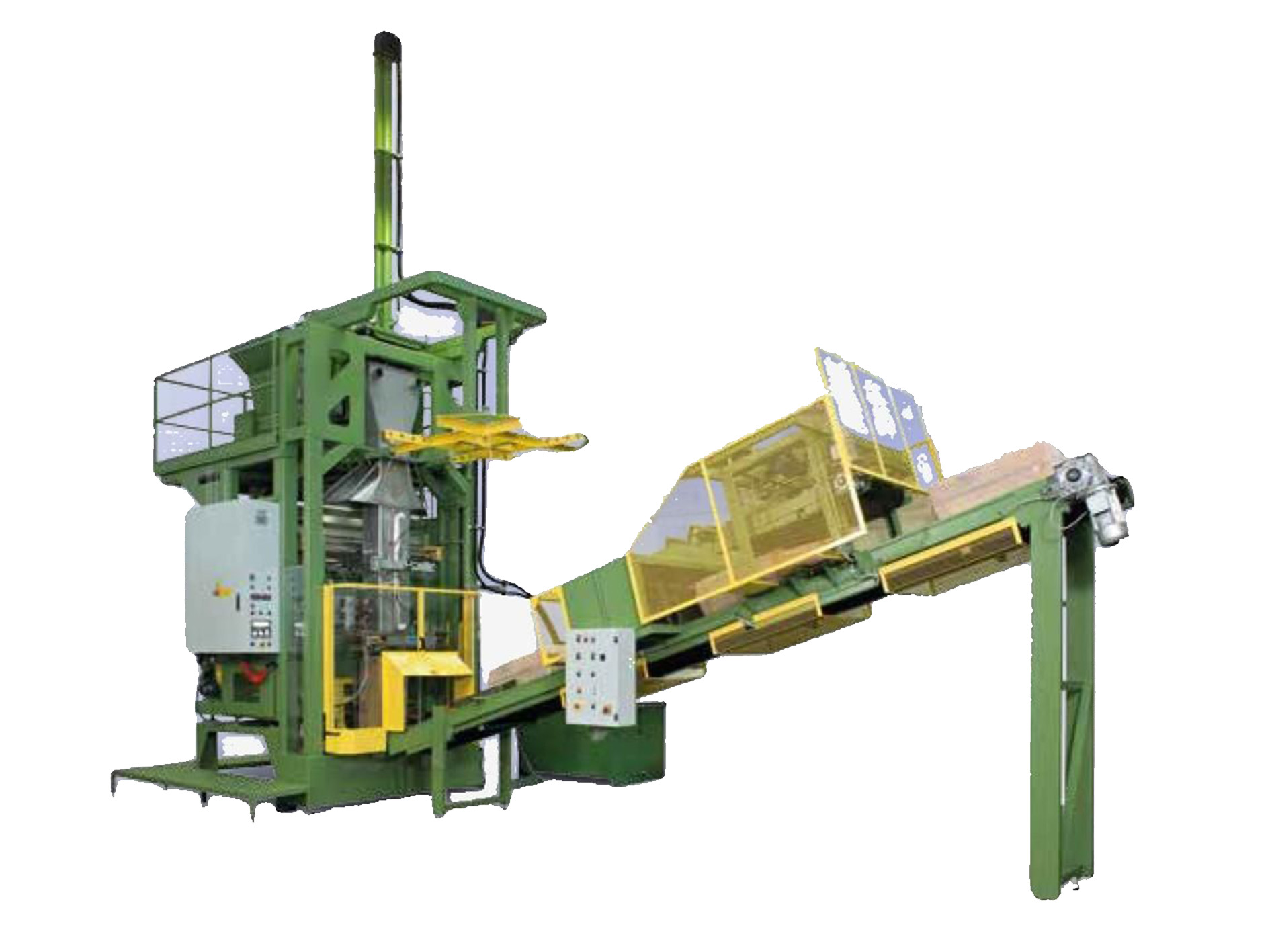

The CV5080 is purpose-built for handling difficult-flowing materials like bark, peat, and silage. Fitted with robust DNSTAR belt dosing systems, it’s a reliable solution for agricultural, landscaping, and biomass industries where strength and consistency are critical.

Mixing & Conveying Solutions in Ireland

At GMK Maintenance Services based Dungannon, we supply and support B&C’s precision-engineered material handling systems — including mixers, hoppers, and conveyors — across Ireland and Northern Ireland. All systems are designed and manufactured in Italy, with full local installation, commissioning, and maintenance provided by our team.

Looking for a turnkey solution? We handle everything from system design to long-term support.